Heat soaking is a destructive process in which a pane of toughened glass is subjected to temperatures of 280° for several hours over a specific temperature gradient, to induce fracture. This test ensures that if there is probability of breakage, caused by naturally occurring elements of nickel sulphide (NiS) having been present when the glass was produced, then the infected panes break inside the furnace. Up to 95% of NiS infested panels are usually destroyed inside the heat soak chamber at the factory and hence reducing the chances of onsite breakages.

The heat soaking process is one method of reducing the incidence of NiS induced failure in toughened glass, by causing the phase change to occur before the glass is installed in the building. The heat soaking process is not 100% effective and failures have been known to occur in rare circumstances.

Based upon the European rate of Nickel Sulphide inclusion, there will be one critical inclusion in every 4 tons of glass, an understanding of the problem by manufacturers has caused them to take steps to eliminate this impurity.

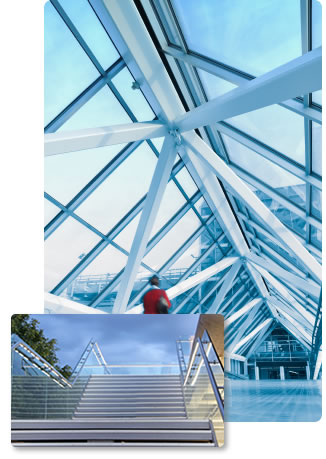

Typically used for:

- High rise glass facades.

- Overhead glazing.

- Balconies and balustrades.

- Any application where a superior toughened glass is required.

Heat soaked glass from Wholesale Glass is processed in various types and thicknesses, including:

Clear, low iron, low-emissivity, satin, a wide range of tinted solar control, anti-sun grey / bronze / green / blue, self cleaning and various patterns.

4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm.

|

|

|

|

|

|

|